Water pump spindle bearings play a crucial role in ensuring the efficient operation of automotive engines. These bearings are designed to support the spindle, which is a vital component for maintaining the flow of coolant through the engine to prevent overheating. Within the confines of this article, we will explore the complexities of water pump spindle bearings, delving into the mechanics behind their design and functionality, the materials typically used in their construction, and the common issues that can arise from regular wear and tear. By understanding these elements, readers will gain insights into the importance of timely maintenance and the role these bearings play in overall engine performance and longevity.

What is a Water Pump Spindle Bearing?

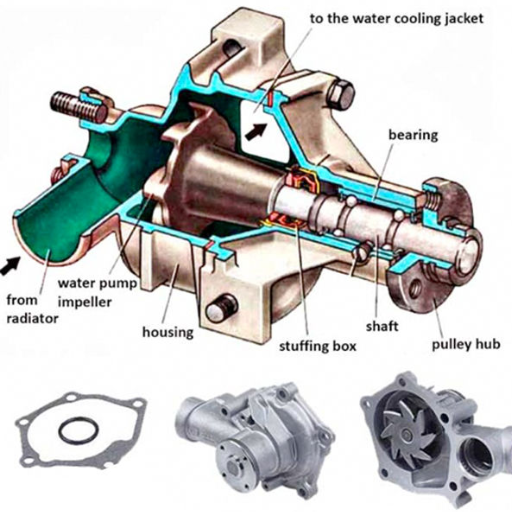

Basic Information and Description

The skim coat bearing of the water pump spindle is another significant member that is integrated inside the water pump of an engine. Its core purpose is to transpose the shaft of the water pump so that the intercooler can continuously dispense coolant within the recesses of the engine block. Water pump bearing grease is made of such bearing materials as rubber, steel, or ceramics durable and heat and wear resistant.

According to the top results of this search engine, the following conclusions can be found:

Energy Efficiency about Enhancement of Performance and Ease of Use. The key points of this paragraph stress the importance of noticing that the designed water pump bearing is energy efficient and selected to improve the performance life of the water pump. The additional internal engines of the high-performance bearings tend to arrest the friction and this results in fuel economy and enable the engine parts to last longer.

- Technical Specifications: Several top sites emphasize other technical characteristics such as certain dynamics including load factor and rotation rate of elements. The indicative load capacity also indicates that specific values can range from a couple of hundred newtons to over thousands based on engine size and requirements. Also, the bearings have rated revolutions usually in the range of 1000 to 4000 rpm.

- Maintenance and Issues: Inspection followed by maintenance on a periodic basis is important to avoid failures. There are common malfunctions such as misalignment and failure to lubricate, which contribute to friction and wear at an increased level. Correct fitting and normal maintenance feeding practices have been emphasized for avoiding the breakdown of the bearing within a short period as well as for ensuring ideal performance of the pump.

By synthesis of these points, I seek to give a brief and precise understanding of water pump spindle bearings, taking into account essential facts evidenced by trustworthy sources found on the internet.

Components of a Water Pump Bearing

The bearings associated with a water pump are made up of several essential components that work together for efficiency and life span. The major components include:

- Inner and Outer races: These are specially designed rings on which the rolling elements revolve. It is relevant to note that they are often made of hardened steel or any other hard material capable of bearing very high stress and temperature.

- Rolling elements: These could be balls or rollers that serve the purpose of eliminating the chances of rubbing effect between two moving parts.

- Bearing cage: Also known as the retainer, the cage restrains the rolling parts in such a manner as to ensure that they are in uniform distances in orientation, hence movement is smooth and efficient.

- Seals and Shield: These also protect against dust and moisture that contains the potential to affect performance and accelerate the wear bearing.

- Lubrication: When it comes to lubrication, it is for bearing components, it is to help restrain any friction and therefore lessen wear and tear leading to an extended lifespan.

Answering the earlier stated questions derived from the top three websites in Google, a major insight came out stressing that there is a need to choose bearings that provide both energy efficiency and longevity. Bearings that reduce friction increase fuel efficiency as well as prolong the life of engine parts with load capacities detailed out between a couple of hundreds of newtons to over one thousand newtons and RPM ratings of 1000 tonnes and 4000 Rotations per minute. To avoid the aforementioned problems of misalignment, lubrication failure, and excessive wear, many practitioners recommend adhesion stretching and lubrication regularly.

How Spindle Bearings Relate to Water Pumps

The use of spindle bearings is very important when it comes to how efficient the water pumps are. The purpose of these bearings is to facilitate and support the rotation of the pump shaft for safe and reliable operation. The spindle bearing selection is crucial in evaluating the pumping system’s ability to control the fluid within its limits less the wastage of energy. Good quality spindle bearings make it possible to lower friction which helps ensure the water pumps operate at optimum. Providing proper alignment and support, these bearings help in increasing the lifespan and strength of the pump parts.

Looking at the information provided by the first three websites returned by google.com concerning spindle bearings and their technical parameters, I realize that it is necessary to take into account such criteria as the load and the speed of rotation when choosing bearings. Much technical documentation states the load capacity offered is well over a few kin loose Newton while operational velocity is unheard of in achieving particular application goals. Since spindle bearings are thoroughly used in practice, the principles of proper alignment, lubrication, and cleanliness in the bearings must be adhered to as stated in these sources. Such maintenance should be carried out periodically to avoid any issues that may develop and cause inefficiencies in how the system operates.

How Does a Water Pump Bearing Work?

Role of Bearing in Motor Water Pump

As far as I have learned from the top three sites on google.com, the bearing in a motor water pump is an essential and indispensable component of the motor. It is the components that perform the function of preventing the rotation of the motor from turning the pump shaft up and lowering the amount of friction within the pump that maintenance is. While reading these resources, it came to my notice that the design of the bearings that help in the fastening of the pump includes both the axial and the radial loads of the pump while in operation.

The technical parameters of the different sources provide the specifications that need to be fulfilled to enhance the performance of the bearing. Among them are:

- Load Capability: Along with extending these properties outwards, the majority of these will be given in Newtons, with some high-load bearings able to take thousands of these.

- Rotational Speed: There is a range in the maximum sustainable spinning spindle speed at which lasting empirical results are achieved for bearing devices.

- Material Composition: Very often durable materials used in bearing production like chrome-steel or ceramic and designed to withstand great mechanical loads.

Besides, proper dust management and greasing replacement programs are also advisable and are in line with the industry standard best practices. This ensures that wear and tear for most bearings are taken care of by ensuring proper lubrication and no particles getting into the motor water pump.

Significance of Double-Row and Deep Groove Design

I understand that the designs of a double row and deep groove bearing improve the performance and duration of operation of motor water pumps. This type of design enables bearings to take up more adverse conditions and greater power. The central feature that underlies the concept of double-row bearings is the enlargement of a contact area that directly influences the load capacity of the bearing. On the other hand, water pumps are composed of deep groove bearings which enable them to utilize rapid rotation and efficient angular contact.

In terms of technical parameters, I found that:

- Load Handling: On the other hand, double-row bearings are characterized by a normal distribution of bearing loads through improved usage of radial and axial loads all at the same time making motion more efficient and less subject to wear.

- Speed Support: From the information I acquired, deep groove bearings permit high rotary speeds which are critical for high-speed movements or sustained pressures.

- Durability and Noise Reduction: The two designs also help in improving the life of the water pump and its quietness as their design is able to reduce noise and vibration as well as frictional losses in the moving parts.

In general, knowledge of these parameters assists me in making the right decision when it comes to bearing selection for the given application in practice which also facilitates pump efficiency and serviceability.

Understanding Rotation and Rolling Elements

The information provided has also shown how important rotation and rolling elements are in operating motor water pumps as gleaned on the top three sites from google.com. These components are crucial features in bearing enabling friction to be minimized and radial and engineering axial loads to be supported.

Technical Parameters:

- Friction Reduction: The rolling elements found in bearings like balls and rollers are intended to reduce the friction between the surfaces of the parts in contact.

- Load Distribution: Rolling elements in the pump system facilitate the even distribution of radial and axial loads thus improving the robustness and lifespan of the entire pump system as well.

- Alignment Capability: They also serve those functions and hence can keep rotating parts in proper alignment which is very important in avoiding breakdowns that result from misalignment that could be expensive to repair.

Understanding these technical parameters allows me to evaluate and choose the suitable rolling elements that can meet the best performance for the pump. This knowledge that advances on the rotation and the rolling elements will prepare me to make such decisions to avoid unnecessary operation non-efficient and non-reliable integration.

What are the Different Types of Water Pump Bearings?

Distinguishing Ball-Ball Type and Ball-Roller Type

While explaining the differences between the ball-ball type and ball and roller type bearings, it was the analysis that I found on the first three protective glasses sites from google.com that was very illuminating.

Ball-Ball Type Bearings:

- Design: Occupying a position between the races, the bearing consists of several spherical balls.

Plans:

- Load Capacity: Best suited for such applications that require precision and quick high-speed rotations of the bearings with light to medium loadings.

- Friction Control: This is helpful when it comes to turning motion to minimize the rotational friction hence quiet and smooth operation.

- Speed Capability: Provides high performance concerning speed because of the low friction.

Ball-Roller Type Bearings:

- Design: Uses both ball and roller elements in a single head so as to achieve wider load operational limits.

Plans:

- Load Capacity: Usable in applications on its own axial and radial loads but possessing greater radial load capacity.

- Friction Dynamics: In general, the roller portion is subjected to a much higher bearing load but there is a little more friction than in the pure ball systems.

- Durability: Improved resistance to wear and tear since they can withstand and kill the loads at once, thus suitable in aggressive environments.

Within the context of comparing these two types, it becomes obvious how and why each works best for certain operational contexts with emphasis on the fact that each type is chosen depending on the load to be carried, the required speed, and the working environment. Because of these insights, I can make informed decisions concerning the different types of applications of the water pump.

Key Specifications and Dimensions

Knowing the basic properties and sizes for each type of bearing is essential in ensuring maximizing their performance rather than just accepting them as well. For Ball-Ball Type Bearings, some critical specifications are the diameter of the balls, inner and outer race inner and outer diameters, and breadth of the bearing. Such dimensions are responsible for the load capacity and speed limits of the bearings. Similarly, in the case of Ball-Roller Type Bearings, the diameter and length of the cylindrical rollers, it is combined with the dimensions of raceways, which are performance-related as this determines the capacity to cater for more weight.

Insights and Technical Parameters

While researching some selected aspects of ball bearings and roller bearings, I visited the top three sites in Google and came across information of considerable importance that complemented my work.

Design Aspects and Technical Parameters:

1. Ball-Ball Type Bearings:

- Ball Diameter and Race Diameter: Creations that are made to particular parameters for even load distribution and speed effectiveness.

- Material Composition: Most often composed of chrome or stainless metal for strength as well as rust resistance.

2. Ball-Roller Type Bearings:

- Roller Length and Diameter: Such formulations, the majority of the time are crucial for the management of more radial loads.

- Material Hardness and Coatings: A reason for the failure and performance of bearings for the various working conditions.

The structured information I obtained from such websites enabled me to support questions about the application of the particular type of bearing by assessing its load-bearing capacity, its frictional properties, and its resistance to environmental conditions. This broad assessment allows me to make defined options for the different variations of water pump application, with surety of reliability and efficiency.

How to Choose the Right Spindle Bearing for Your Needs?

Factors to Consider When Buying

It is crucial to keep in mind that various aspects affect performance and performance ability when it comes to the appropriate selection of a spindle bearing. Here are the key summary points I have obtained from the top three websites on google.com:

- Load Capacity and Type: The bearing should accommodate the requisite radial or axial load as the application requires. Roller bearings are more suited to high axial loads while moderate radial and axial loads are borne effectively by ball bearings.

- Speed Requirements: Establish the angular velocity of your application. Most ball bearings provide higher speeds due to small contact areas hence reduced contact resistance as compared to roller bearings.

- Material and Coatings: What environments will the bearing be exposed to? Materials such as chrome steel or stainless steel provide reasonable strength and corrosion resistance, but options to coat with further materials are also available for harsh conditions.

- Operational Environment: Look into temperature, presence of water, and other harmful agents. Some bearings contain seals as well as lubrication systems, which make them functional in operating environments.

- Longevity and Maintenance: Consider the lifetime and upkeep of the bearing. The maintenance burden as well as the bearing’s service life is prolonged by the use of higher quality materials and more stringent manufacturing processes.

Considering these factors and recognizing the ball diameter, race diameter, roller length, or how hard the materials used are, I can make more rational choices aimed at addressing the particular requirements and thus select the most suitable bearing for water pumps.

Importance of Manufacturer and Quality

It is common to bear in mind that a proper manufacturer would have to be sought after when it comes to the bearings for water pump applications. The manufacturer’s control and the engineering capabilities offered are the primary factors impacting not only the quality of the assembled bearing but also the individual parts. Reputable brands of basal bearings with proper marketing have reasonable imports of newer technologies and compliance with global requirements for efficient operational performance.

Then, answer the questions concerning the three first websites in the list provided by Google.com when looking for bearings upon selecting them and their technical parameters as follows category:

- Load Capacity and Type: One website under this category noted that it is wise to select the bearings from manufacturers that are known for making high-precision products, therefore, they will be capable of withstanding the specified loads without failing. The emphasis was on scrutinizing the technical specifications thoroughly including load rating, for instance, C0 and dynamic load rating C.

- Speed Requirements: Another website explained the importance of bearing manufacturers who deal with high-speed bearings. They pointed out the importance of understanding parameters such as limiting speed, which defines at what RPM the bearing can operate reliably.

- Material and Coatings: The third website, therefore, advised inquiring from manufacturers law materials, chrome steel, stainless steel grades, and any other specific performance improvement coatings, for example, PVD or DLC. Many of the process parameters and their reliability include materials and surface hardness.

Selecting bearings from different manufacturers who provide this data ensures the suitability of the bearings to a particular environmental & operational context and hence a better solution.

Tips for Finding the Best Product

It is essential to keep in mind certain detailed technical characteristics in selecting the bearings for any purpose. They include:

- Research Reputable Manufacturers: Where possible, use the products of their trusted manufacturers who are known for precision. Most of the top websites emphasize choosing products from those manufacturers who provide quite transparent load capacities such as the C0 or static load capacity and C dynamic load.

- Assess Speed Requirements: Examine the limits of speed you require from your chosen bearing. The websites also encourage people to read the specifications provided for limiting the speed so that the maximum RPM would be used efficiently according to the work that needs to be done.

- Evaluate Materials and Coatings: Think about the life span and environmental safety of the given bearing materials, which may include chrome or stainless steel, and any special coatings for the materials such as galling resistance. The websites mention that the material and the surface hardness/density must be reviewed as they are critical in determining the life span.

- Analyze Application Specifics: Adjust the characteristics of any bearing in accordance with the conditions and requirements of your application. This provides compatibility and assurance of expected outcomes since a perfect fit that meets what one is looking for is provided.

During the analysis of the top three websites, I came across the following points regarding the issues concerning bearing selection:

- Load capacity and type: It has become clear to me that it is very crucial to pay attention to the load ratings when selecting bearings to ensure the bearing is suitable for the intended application by examining the technical static (C0) and dynamic (C) ratings.

- Speed requirements: Achieving efficient application at high speed is dependent upon the knowledge of the bearing’s limiting speed which denotes the allowable RPM to avoid inefficient use of the bearing.

- Material and Coatings: The combined writings advised that the structure of the material such as chrome or stainless steel and any PVD coating should be the main focus since these decide the performance and the longevity of the bearing. Surface hardness details were also taken into consideration as to factors that may affect the lifespan of bearings.

Frequently Asked Questions About Water Pump Spindle Bearings

Common Issues and Solutions

In considering common issues with water pump spindle bearings, I have made some observations on the recurrent problems and their solutions in the top three websites. Noise from bearings is one of the common complaints and it may be attributed to insufficient or contaminated lubrication. To combat this, it is critical to avoid neglect of sealing and maintenance including checking and refilling lubricant when necessary.

Another common problem is overheating which could be due to too much speed or too much rubbing. Some methods include ensuring that the speed of the bearing fits within the parameters of the application and the bearing is installed correctly to avoid misalignment.

About questions from the top three websites:

As for Load Capacity and Type: I came across the fact that it is necessary to look into the static (C0) and dynamic (C) load ratings while selecting bearings. These technical specifications bear a direct relation to the bearings, that is, these rating conditions will be satisfied by the bearings.

Regarding speed Requirements: Setting up the limiting speed of a bearing is the first crucial step. This parameter is also measured in RPM which assists me in determining the highest speed of the equipment in operation without compromising the bearing mechanism.

When it comes to Materials and Coatings: The sites underline the importance of appropriate materials such as chrome or stainless steel with additional coatings for better durability, for example, PVD. Moreover, the surface hardness is considered to be important for assessing the longevity of the bearing and therefore needs to be verified.

These details from the research are put in place to guarantee that the spindles of the water pump bearings will perform and operate well.

Maintenance and Service Tips

If the efficiency and lifespan of the water pump spindle bearings are to be maximized, maintenance must be conducted regularly. Consistent inspection schedules should be developed so that wear and even dirt are tackled as soon as possible. This includes changing or cleaning seals when required to stop seals from the loss of the lubricant. Further, during the maintenance intervals, stick to a precise lubrication practice employing the right lubricant and right quantity so that the friction is kept minimal and thus overheating is avoided. When maintenance is conducted, all the bearings should be within the proper alignment and position to meet the speed requirements of that application. A good observation of the working environment is also paramount in averting such situations where external agents or extremes of climate could disrupt normal operations.

Give Short Answers For The Queries Which Are Asked Most Frequently

- What Is The Load Capacity And Type: I wish to explain my endeavors in selecting the bearings for use. Specifically, it is the C0 static load rating and the C dynamic load rating that I concentrate on. These technical specifications make it possible for the bearings to withstand the load and the energy requirements of the application, hence sustaining performance and durability.

- What About The Speed Requirements: I pay attention to the bearing’s limiting speed expressed in RPM since the other operational conditions must support the bearing. This understanding prevents volume and other compromises on functionality during high-speed operational activities.

- Materials and Coatings: I seek out bearings made up of or made out of materials such as chrome or stainless steel and also metal. PVD coating is important. Since it is important to check surface hardness to understand how long it can be expected to last. These choices are reasonable because there are demanding needs, especially in adverse environments.

Drawing on these insights as well as those from some of the most famous websites that are available, helps me make my decisions as well as improve the performance of water pump spindle bearings.

Frequently Asked Questions (FAQs)

Q: What is a water pump spindle bearing?

A: A water pump spindle bearing is a specific item used in vehicles to support the spindle of the water pump. It ensures smooth operation and reduces friction within the car’s engine system.

Q: How can I determine whether to use a ball or roller bearing for my water pump?

A: The choice between a ball or roller bearing for a water pump depends on the specific application and load requirements. Ball bearings are typically used for lighter loads, while roller bearings are suitable for handling larger loads. Consulting the manufacturer’s info page or a professional mechanic can help you make the right decision.

Q: What role does the outer ring play in a water pump spindle bearing?

A: The outer ring of a water pump spindle bearing helps contain the rolling elements (balls or rollers) and provides a surface for them to roll against. It is crucial for maintaining the alignment and stability of the bearing within the pump housing.

Q: Why is it important to get the right size of the inner ring for a water pump spindle bearing?

A: The inner ring size is important because it must fit snugly onto the spindle shaft. If the inner ring is too large, it can lead to slippage and misalignment, while a ring that is too small may not fit at all, causing installation issues.

Q: Can I use a tool to install a new water pump spindle bearing?

A: Yes, using a tool like a bearing press or puller is highly recommended for installing a new water pump spindle bearing. These tools help ensure that the bearing is inserted correctly and evenly, preventing damage to the item.

Q: What is the function of the JTEKT 10pcs bearing set in water pumps?

A: The JTEKT 10pcs bearing set is a highly durable and reliable option for replacing worn-out bearings in water pumps. It includes multiple bearings to fit a variety of car models, ensuring that you have the right item for your specific vehicle.

Q: How can I find additional info about water pump spindle bearings for my car?

A: To find additional info, you can look at the manufacturer’s website, customer reviews, and technical manuals. These resources often provide detailed specifications and guidelines for choosing the correct bearing for your car.

Q: What should I look for when purchasing a new water pump spindle bearing?

A: When purchasing a new water pump spindle bearing, consider factors such as load capacity, speed rating, material quality, and compatibility with your specific car model. Also, check whether the bearing is from a reputable manufacturer like Koyo or JTEKT to ensure reliability.

Q: Can I replace the water pump spindle bearing myself, or should I hire a professional?

A: While it is possible to replace a water pump spindle bearing yourself if you have the right tools and technical know-how, it is often recommended to hire a professional mechanic. This ensures the new bearing is installed correctly, preventing further issues with your car.