Mud Pump Bearing

Home » Mud Pump Bearing

-

Understanding Mud Pump Bearing

However, a new line of AMIGO Mud Pump Bearings is ready to separate itself from the pack by offering outstanding performance even in the most extreme conditions. Our bearings are designed to resist the negative factors associated with mud pumps and provide reliable support. All such AMIGO Mud Pump Bearings are made free-style and replace leading bearing units of other companies. The tools’ practical efficiency and working capability enhanced with this bearing will never disappoint your expectations! Count on AMIGO for high-level quality while drilling operations.

Features and benefits

- High Load Capacity: Built for heavy radial and axial loads working in extreme conditions.

- Durability: Manufactured from rugged materials for long life in extreme environments.

- Interchangeable Design: Industry compatible, making changes and maintenance relatively easy.

- Corrosion Resistance: Mud and exposure to chemicals have enhanced serviceability.

- Low Friction: Design and performance have been made better with minimum friction.

- Temperature Tolerance: Furniture that can withstand high temperatures does not perform at all.

Temperature Limits

Several factors may place restrictions on the operating temperature limit for the alignment mud pump bearings, though these are not exhaustive:

- Operating Temperature Range: The values typically range between -20 degrees Celsius and 120 degrees Celsius, which is -4 to 248 degrees Fahrenheit, depending on the bearing material used.

- High-Temperature resistance: Certain designs can operate with temperatures not exceeding 150 degrees centigrade, though it is not longer than an hour.

- Low Temperature Applications: Some bearings are useful up to -40 degrees centigrade. It can also accept the same in Fahrenheit.

- Lubrication Issues: Make sure that the temperature of the lubricant is within its effective range to avoid logging.

To ensure alignment is maintained, thermal expansion effects must be considered in situations where excessive heat will be experienced.

Applications

- Oil and Gas Drilling: Crucial in the processes of mud circulation during drilling activities.

- Geothermal Energy: Used for working with drilling fluids in drilling rigs for geothermal energy.

- Mining Operations: Assists in the mud pumping during the extraction of minerals.

- Construction Projects: Helps in the clearance of the mud after a differential boring.

- Environmental Remediation: Employed in schemes for the decontamination of soil and water.

- Piling and Tunneling: This guarantees the necessary work of pumps used in construction and tunneling.

Mud Pump Bearing Size Chart

| Designation | Principal dimensions | Bearing Dimensions Chart Pdf | ||

|---|---|---|---|---|

| d[mm] | D[mm] | B[mm] | ||

| WB1630085 | 30 | 84.99 | 13 | Download |

| WB1630105.5 | 30 | 105.51 | 23.54 | Download |

| WB1630110 | 30 | 110.39 | 21.41 | Download |

| WB1630101 | 30 | 101.5 | 17.5 | Download |

| WB1630103 | 30 | 102.62 | 22.5 | Download |

| WB1630106 | 30 | 105.97 | 20.7 | Download |

| WB1630109.5 | 30 | 109.52 | 14.68 | Download |

| WB1630111.5 | 30 | 111.51 | 23.85 | Download |

| WB1630154-2 | 30 | 154.23 | 29.77 | Download |

| WB1630161 | 30 | 161.93 | 58.42 | Download |

| WB1630141 | 30 | 141 | 48.92 | Download |

| WB1630119 | 30 | 119.05 | 37.36 | Download |

| WB1938136 | 38.1 | 136.7 | 40.26 | Download |

| WB1630146 | 30 | 146.05 | 61.72 | Download |

| WB1630139 | 30 | 139.32 | 35.05 | Download |

Customize bearings to meet your specific needs.

Are you looking for bearings tailored to your unique specifications? Our customization service ensures that each bearing is designed and manufactured to meet your requirements, providing the perfect solution for your application. Click the "Enquire Now" button to discuss your needs with our experts and get started on your custom-bearing solution today.

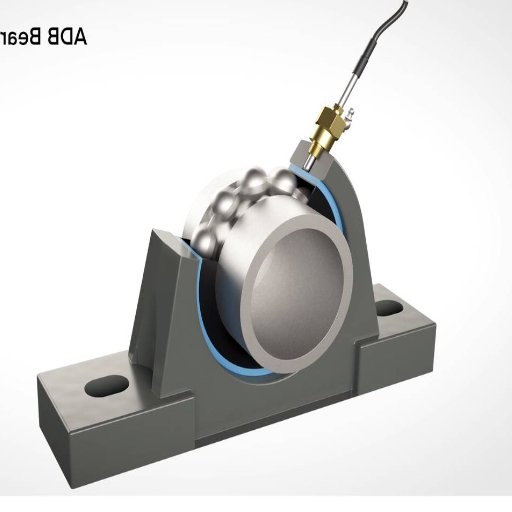

Mud Pump Bearings - Designs and Variants

- Single Row Bearings:

Ideal for standard applications with moderate load requirements, providing reliable performance. - Double Row Bearings:

Offers higher load capacity and stability, suitable for heavy-duty mud pumps operating under demanding conditions. - Angular Contact Bearings:

Designed to handle both radial and axial loads, making them suitable for applications with directional forces. - Sealed Bearings:

Equipped with seals to prevent contamination and retain lubrication, enhancing durability in abrasive environments. - High-Speed Bearings:

Optimized for performance in applications requiring higher rotational speeds, ensuring efficient operation. - Corrosion-Resistant Bearings:

Made from specialized materials to withstand exposure to aggressive drilling fluids and harsh environments. - Self-Aligning Bearings:

Compensate for shaft misalignment, promoting smoother operation and reducing wear.

Mud Pump Bearings Loads

Radial Loads

These loads originate mainly from the mass of the rotating shaft and the attachments it carries.It emanated from the forces related to the pumped mud.

Axial Loads

These result from differences in pressure in the mud pump, especially when working. It was hinged on the configuration of the pump and the type of drilling fluid used.

Combined Loads

There is also constant axial and radial load acting on the mud pump bearing during operations. Bearings must be carefully designed for this factor; that is, they must withstand these two loads.

Dynamic Loads

Vary because of changes in the operation parameters (pump speed, fluid viscosity etc). Bearings must be rated for gradual variations in loads through time.

Mud Pump Bearing Catalogue

This PDF document PDF is aimed at making the reader less ignorant about what AMIGO Mud Pump Bearings are, their advantages, temperature limits, and their operating conditions. Interchangeable with the leading brands and built for adverse drilling conditions, our mud pump bearings are designed to be robust and dependable under demanding drilling conditions. Download the PDF to understand the complete description of the products and ensure the most efficient drilling operations.

Explore More on Bearings

Mud Pump Bearing FAQ

What do mud pump bearings support, you ask?

Mud pump bearings play a crucial role in mud pump operations as they facilitate the rotation of the shaft, which is important equipment used in drilling. They also help control the radial and axial loads, offering reliable functionality under difficult operating conditions.

How do I know the suitable mud pump bearings I need for my application?

To select the bearings, the load capacity, operating temperatures and environments, and degree of integration with the current machinery should be taken into account. It is best to follow the manufacturer’s guidelines.

What kind of loads do the mud pump bearings address?

The axial loads are usually created by the pressure variation during the use of the mud pump, which also includes the radial load due to saddle weight. This is extremely important for practical bearing specification.

Do AMIGO mud pump bearings fit other brands of pumps?

AMIGO mud pump bearings are also manufactured to be fixed to other known brands, enabling easy swaps in place without effecting the wall’s performance.

How do I increase the working life of my mud pump bearings?

Working life can be extended through maintenance such as lubrication, checking on wear and tear, and ensuring that the bearings are within the permissible range of loads and operating temperatures.

What are the features of sealed and unsealed mud pump bearings?

Filled types of bearings are fitted with sealing caps that protect from intrusion of dirt and oil retaining safes, making them useful in unfavorable environments. Oiled Filtrating bearings are handled up and do not hold filmando after centrifugation. The milage holders may outlast the depth and may use oil infrequently. Import circling service-orientated designs will encumber more often.

What maintenance has to be done on the mud pump bearings?

The maintenance carried out in this case consists of controlling the wear and tear of the components of parts, especially the bearing, frequent lubrication of the lubricating device, and control of the device temperatures and vibrations in operations. When these factors are addressed, premature failures can be avoided.